Rigid Plastic Packaging Market Size

| Study Period | 2017-2027 |

| Market Size (2023) | USD 247.54 Billion |

| Market Size (2028) | USD 278.07 Billion |

| CAGR (2023 - 2028) | 2.35 % |

| Fastest Growing Market | Asia Pacific |

| Largest Market | Asia Pacific |

Major Players

*Disclaimer: Major Players sorted in no particular order |

Need a report that reflects how COVID-19 has impacted this market and its growth?

Rigid Plastic Packaging Market Analysis

The Rigid Plastic Packaging Market size is expected to grow from USD 247.54 billion in 2023 to USD 278.07 billion by 2028, at a CAGR of 2.35% during the forecast period (2023-2028).

According to Plastics Industry Association's Rigid Plastic Packaging Group (RPPG), Plastics account for one-third of the global packaging industry, and much of this plastic packaging is rigid.

- Packaging made of rigid plastic is durable, affordable, and environmentally friendly. A significant market driver for rigid plastic packaging is the rising need for environmentally friendly and sustainable packaging solutions. Potential growth prospects are being created for manufacturers.

- The convenience packaging industry influences the rigid plastic packaging market since busier lives call for items that can be consumed while on the move and cut down on cooking time. The need for rigid packaging will also be fueled by increased disposable income and expanding packaged-goods consumption in emerging nations.

- Augmenting demand for biodegradable rigid plastic packaging is expected to boost the market growth in the future. Also, people moving towards beverages and other household care products positively impact the rigid plastic packaging market. Moreover, rapidly increasing urbanization also contributes to market growth. Furthermore, the growing disposable income of the people will positively impact market growth in the coming future.

- The growing demand for rigid plastic packaging from the healthcare industry is also one of the critical factors that has triggered the market's growth in recent years. Rigid plastic helps enterprises in the healthcare industry protect medicines from contamination. The medical product packaging must be compliant with international regulatory standards for safety. Therefore, the properties of rigid plastic, along with its durability, light weight, cleanliness, and transparency, make it the perfect choice for storing medical products.

- However, high competition for advanced rigid plastic packaging may hinder market growth. Also, increasing the use of BisphenolA (BPA) in manufacturing plastic products poses a significant challenge for the overall rigid plastic packaging market. Raw material volatility is another major stumbling block to the market's expansion. Crude oil is the primary raw material used in plastic-based products, and price fluctuations in crude oil impact the pricing of the finished goods.

- With the outbreak of COVID-19, rigid plastic packaging witnessed growth owing to the demand for essential services, such as personal and healthcare products. A spike in products, such as HDPE containers, pumps, and pharmaceutical bottles was witnessed. However, with many countries under lockdown and restricted movement across them, demand for the packaging of non-essential industries decreased.

Rigid Plastic Packaging Market Trends

This section covers the major market trends shaping the Rigid Plastic Packaging Market according to our research experts:

Polypropylene (PP) to Account for Significant Market Share in Rigid Plastic Packaging Market

- Compared to other plastic materials like polyethylene, polyethylene terephthalate (PET), polystyrene (PS), and others, polypropylene offers superior barrier qualities, improved surface polish, cheap cost, and high tensile strength. These features make polypropylene ideal material for a range of packaging applications. Some of the growing applications for polypropylene include medicine bottles, bottles for ketchup and syrups, and bottle caps and closures. The market for rigid plastic packaging will thus continue to increase over the projected period due to the rising demand for polypropylene (PP) material.

- Medicine bottles, bottle caps and closures, and bottles for ketchup and syrups are some of the increasing applications of polypropylene. For instance, under its brand, Magnum, Unilever launched ice creams in tubs made from recycled PP plastic packaging, which was the first in the ice cream industry. The move was part of the company’s broader strategy to ensure that 25% of its plastic packaging will come from post-consumer recycled content by 2025.

- Further, according to a report by PlastIndia Foundation, India has a manufacturing capacity of 4,970 Kilo Ton per Annum (KTA) for Polypropylene (PP). According to IBEF, India is progressing in plastic industries with 30,000 plastic processing units, and about 4 million people are employed in these industries.

- Furthermore, according to the American Chemistry Council, the capacity to produce polyethylene, the plastic resin most influenced by the abundance and low cost of shale gas, is expected to grow more than 50%. The price of shale gas was further dampened due to poor market weather, which was turbulent due to the COVID-19 pandemic. Polyvinyl chloride and polypropylene resins are also anticipated to benefit from abundant, affordable shale gas.

- Also, as per ITC statistics, the global imports of polymers of propylene in 2021 were recorded to be USD 58.77 billion, a 42.37% increase from the previous year, 2020. Global imports witnessed a significant recovery rate from the COVID-19 impact and imports in 2021 recorded a 28.6% rise from 2019 imports.

Asia-Pacific to Witness Significant Market Share in the Forecast Period

- The Asia-Pacific region holds a significant market share. Due to their expanding economies and economic activity, the rigid plastic packaging industry is predicted to increase in nations like China and India. In addition, these nations' expanding populations provide a significant market for FMCG goods and consumer durables, which is anticipated to fuel the expansion of the rigid plastic packaging industry.

- The demand for rigid plastic packaging has grown for the forecast period due to significant factors, including industrialization, the growth of the convenience food industry, an increase in manufacturing activities, rising disposable income, rising consumption levels, and rising e-retail sales. Furthermore, the growth of countries like India, China, and Indonesia drives the Asia-Pacific region to lead packaging demand for the global beauty and personal care industry.

- Manufacturers are launching innovative pack formats, sizes, and functionality in response to the consumer demand for convenience. Also, with the growth in oral, skincare, and niche categories, such as men’s grooming and baby care, Asia-Pacific is both an opportunity and challenging region for packaging manufacturers.

Rigid Plastic Packaging Industry Overview

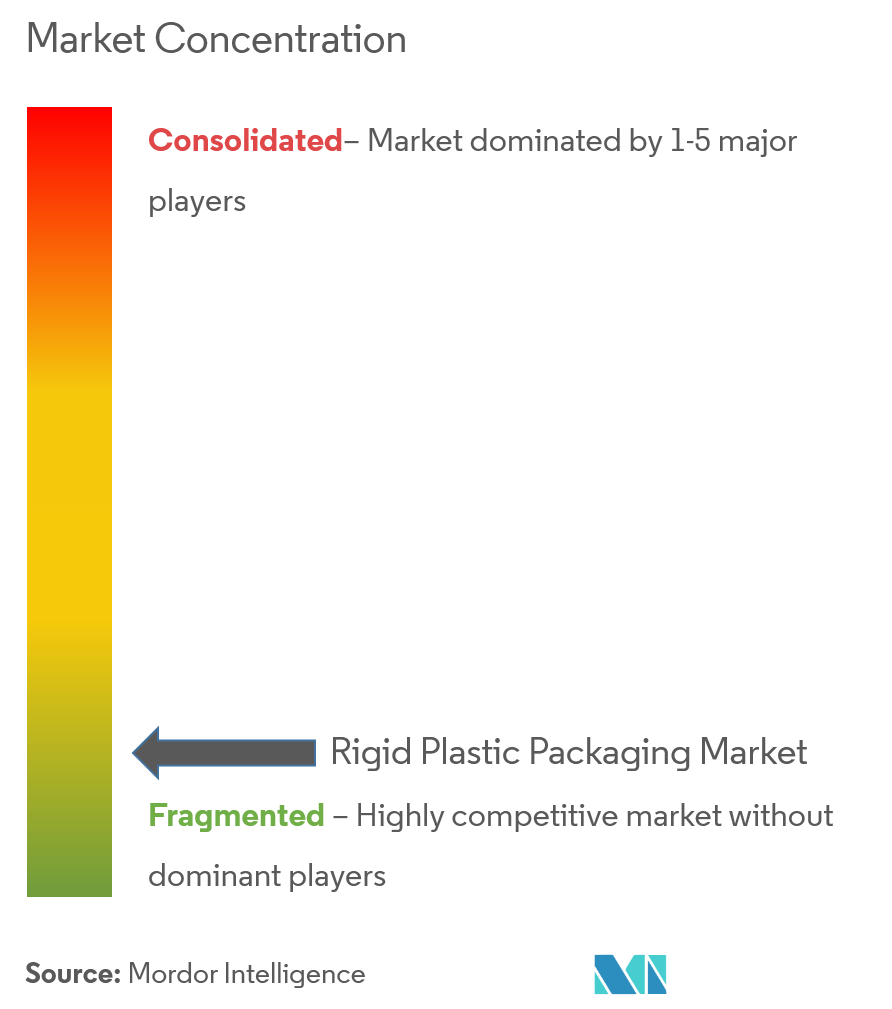

The rigid plastic packaging market is fragmented. Due to the presence of several players, the market has strong competition. Companies focus on providing lightweight, high-performance, corrugated grades to reduce costs and improve packaging performance. Some of the major players in the market are Amcor Plc, RPC Group Plc, Coveris Holdings S.A., ALPLA, Silgan Holdings, Sealed Air, Reynolds Group Holding, Plastipak Holding, Sonoco Products Company, DS Smith, Consolidated Container Co. LLC, Graham Packaging Company Inc., among others

- July 2022, Alpla acquired the Polish company Apon, which makes plastic containers for the pharmaceutical market. Apon creates bottles, containers with screw closures or snap lids, dose aids for medical equipment, food supplement packaging, and e-liquid packaging. The business is expanding its footprint in Central and Eastern Europe and supplying the Baltic nations and Poland's developing markets with quality goods.

- March 2022, Berry Global Group and Koa Corporation, a skincare company, partnered to introduce body moisturizer bottles and cleaners created entirely from recycled plastic. Berry Global and Koa aim to positively influence the environment via simplified business practices, ongoing engagement with partners, and optimized products. The PET bottles are created at Berry's manufacturing plant in Winchester, Virginia, using 100% PCR and silk-screen decorating, which complies with Koa's commitment to sustainability and eliminates the need to account for label materials in the recycling process.

Rigid Plastic Packaging Market Leaders

Amcor Plc

Berry Global Group

Coveris Holdings S.A.

ALPLA Group

Sealed Air Corporation

*Disclaimer: Major Players sorted in no particular order

Rigid Plastic Packaging Market News

- September 2022: Amcor Rigid Packaging (ARP) developed ClearCor to produce DairySeal, a new PET barrier technology for containers of ready-to-drink dairy beverages. The bottles are recyclable and can contain up to 80% recyclable elements in their construction. ARP has created a barrier out of PET film to keep dairy beverages tasting fresh. A "concentrated capsulation" created by new technology designed by ClearCor in the preform's core gives the containers additional flexibility and resin possibilities.

- September 2022: Ingreendients, a personal care company, partnered with Berry Global, a United States-based packaging firm, to create 100% recycled plastic bottles for haircare products. For Ingreendients, Berry Global introduced shampoo and conditioner bottles constructed of post-consumer recycled (PCR) plastic, right down to the cap. The packaging industry makes high-density polyethylene (HDPE) bottles at a factory in Winchester, Virginia.

- September 2022: Sonoco signed a definitive deal to acquire privately held paper company Skjern from Denmark for USD 88 million in cash. Sonoco will be able to convert operations throughout Europe and surrounding regions and increase its client production capacity as a result of the purchase. The purchase is consistent with the packaging company's strategy of investing in its core business while extending Europe's expanding market for sustainable paper and packaging products.

Rigid Plastic Packaging Market Report - Table of Contents

1. INTRODUCTION

1.1 Study Assumptions and Market Definition

1.2 Scope of the Study

2. RESEARCH METHODOLOGY

3. EXECUTIVE SUMMARY

4. MARKET INSIGHTS

4.1 Market Overview

4.2 Industry Value Chain Analysis

4.3 Industry Attractiveness - Porter's Five Forces Analysis

4.3.1 Bargaining Power of Suppliers

4.3.2 Bargaining Power of Buyers/Consumers

4.3.3 Threat of New Entrants

4.3.4 Threat of Substitute Products

4.3.5 Intensity of Competitive Rivalry

4.4 Assessment of the Impact of COVID-19 on the Market

5. MARKET DYNAMICS

5.1 Market Drivers

5.1.1 Increasing Demand in Major Asian Markets Such as India and China

5.1.2 Strong Demand From the Food and Beverage Packaging Industry

5.2 Market Restraints

5.2.1 Stringent Laws & Regulations Pertaining to Plastic Industries

5.2.2 Competition From Flexible Plastic Packaging

6. MARKET SEGMENTATION

6.1 By Product

6.1.1 Bottles and Jars

6.1.2 Trays and Containers

6.1.3 Caps & Closures

6.1.4 Other Product Types (blister & clamshell packs and rigid plastic tubes)

6.2 By Material

6.2.1 Polyethylene (PE)

6.2.2 Polyethylene terephthalate (PET)

6.2.3 Polypropylene (PP)

6.2.4 Polystyrene (PS) and Expanded polystyrene (EPS)

6.2.5 Polyvinyl chloride (PVC)

6.2.6 Other Rigid Plastic Packaging Materials

6.3 By Manufacturing Process

6.3.1 Extrusion

6.3.2 Injection Molding

6.3.3 Blow Molding

6.3.4 Thermoforming

6.3.5 Other Manufacturing Processes (foam extrusion, calendaring and roto molding)

6.4 By End-user Industry

6.4.1 Food & Beverage

6.4.2 Healthcare

6.4.3 Cosmetics & Personal Care

6.4.4 Industrial

6.4.5 Building & Construction

6.4.6 Automotive

6.4.7 Other End-user industries (Electrical & Electronics)

6.5 Geography

6.5.1 North America

6.5.1.1 By Material

6.5.1.2 By Product

6.5.1.3 By End-user Industry

6.5.1.4 By Country

6.5.1.4.1 United States

6.5.1.4.2 Canada

6.5.2 Europe

6.5.2.1 By Material

6.5.2.2 By Product

6.5.2.3 By End-user Industry

6.5.2.4 By Country

6.5.2.4.1 United Kingdom

6.5.2.4.2 Germany

6.5.2.4.3 France

6.5.2.4.4 Italy

6.5.2.4.5 Spain

6.5.2.4.6 Rest of Europe

6.5.3 Asia-Pacific

6.5.3.1 By Material

6.5.3.2 By Product

6.5.3.3 By End-user Industry

6.5.3.4 By Country

6.5.3.4.1 China

6.5.3.4.2 India

6.5.3.4.3 Japan

6.5.3.4.4 South Korea

6.5.3.4.5 Australia

6.5.3.4.6 South Korea

6.5.3.4.7 Indonesia

6.5.3.4.8 Rest of Asia-Pacific

6.5.4 Latin America

6.5.4.1 By Material

6.5.4.2 By Product

6.5.4.3 By End-user Industry

6.5.4.4 By Country

6.5.4.4.1 Brazil

6.5.4.4.2 Argentina

6.5.4.4.3 Mexico

6.5.4.4.4 Rest of Latin America

6.5.5 Middle East & Africa

6.5.5.1 By Material

6.5.5.2 By Product

6.5.5.3 By End-user Industry

6.5.5.4 By Country

6.5.5.4.1 United Arab Emirates (UAE)

6.5.5.4.2 Saudi Arabia

6.5.5.4.3 South Africa

6.5.5.4.4 Rest of Middle East and Africa

7. COMPETITIVE LANDSCAPE

7.1 Company Profiles

7.1.1 Amcor Plc

7.1.2 Berry Global Group

7.1.3 Coveris Holdings S.A.

7.1.4 ALPLA

7.1.5 Silgan Holdings

7.1.6 Sealed Air Corporation

7.1.7 Reynolds Group Holding

7.1.8 Plastipak Holding

7.1.9 Sonoco Products Company

7.1.10 DS Smith PLC

7.1.11 Consolidated Container Co. LLC

7.1.12 Graham Packaging Company Inc.

- *List Not Exhaustive

8. INVESTMENT ANALYSIS

9. MARKET OPPORTUNITIES AND FUTURE TRENDS

Rigid Plastic Packaging Industry Segmentation

Rigid packaging is defined as a packaging type that features heavier and often stronger materials than flexible packaging. Forms of rigid packaging materials include glass, hard plastics, cardboard, metal among others that are offered as corrugated and paperboard boxes, plastic bottles and boxes, aluminum cans, and glass jars. Rigid packaging supplies are usually more expensive than their flexible alternatives. Popular applications include cereal boxes, glass bottles of spirits, cans of soup, and laundry detergent bottles.

The Rigid Plastic Packaging Market is segmented by Product (Bottles and Jars, Trays and Containers, Caps & Closures), Material(Polyethylene (PE), Polyethylene terephthalate (PET), Polypropylene (PP), Polystyrene (PS) and Expanded polystyrene (EPS), Polyvinyl chloride (PVC)), Manufacturing Process (Extrusion, Injection Molding, Blow Molding, Thermoforming), End-user Industry (Food & Beverage, Healthcare, Cosmetics & Personal Care, Industrial, Building & Construction, Automotive) and Geography. The study scope covers the market from a consumption perspective and tracks the market in terms of volume in million metric tonnes.

| By Product | |

| Bottles and Jars | |

| Trays and Containers | |

| Caps & Closures | |

| Other Product Types (blister & clamshell packs and rigid plastic tubes) |

| By Material | |

| Polyethylene (PE) | |

| Polyethylene terephthalate (PET) | |

| Polypropylene (PP) | |

| Polystyrene (PS) and Expanded polystyrene (EPS) | |

| Polyvinyl chloride (PVC) | |

| Other Rigid Plastic Packaging Materials |

| By Manufacturing Process | |

| Extrusion | |

| Injection Molding | |

| Blow Molding | |

| Thermoforming | |

| Other Manufacturing Processes (foam extrusion, calendaring and roto molding) |

| By End-user Industry | |

| Food & Beverage | |

| Healthcare | |

| Cosmetics & Personal Care | |

| Industrial | |

| Building & Construction | |

| Automotive | |

| Other End-user industries (Electrical & Electronics) |

| Geography | |||||||||||||||

| |||||||||||||||

| |||||||||||||||

| |||||||||||||||

| |||||||||||||||

|

Rigid Plastic Packaging Market Research FAQs

How big is the Rigid Plastic Packaging Market?

The Rigid Plastic Packaging Market size is expected to reach USD 247.54 billion in 2023 and grow at a CAGR of 2.35% to reach USD 278.07 billion by 2028.

What is the current Rigid Plastic Packaging Market size?

In 2023, the Rigid Plastic Packaging Market size is expected to reach USD 247.54 billion.

Who are the key players in Rigid Plastic Packaging Market?

Amcor Plc, Berry Global Group, Coveris Holdings S.A., ALPLA Group and Sealed Air Corporation are the major companies operating in the Rigid Plastic Packaging Market.

Which is the fastest growing region in Rigid Plastic Packaging Market?

Asia Pacific is estimated to grow at the highest CAGR over the forecast period (2023-2027).

Which region has the biggest share in Rigid Plastic Packaging Market?

In 2023, the Asia Pacific accounts for the largest market share in the Rigid Plastic Packaging Market.

Rigid Plastic Packaging Industry Report

Statistics for the 2023 Rigid Plastic Packaging market share, size and revenue growth rate, created by Mordor Intelligence™ Industry Reports. Rigid Plastic Packaging analysis includes a market forecast outlook to 2028 and historical overview. Get a sample of this industry analysis as a free report PDF download.